Projects

206 Marylebone Road

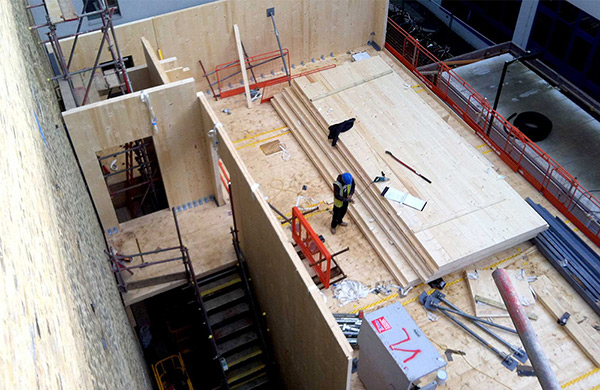

A new eight-storey office on the site of the old National Cash Register Company. The structural scheme demonstrates Davies Maguire's commitment to embodied carbon reduction and innovation in sustainability, through sustainable material use and retention of majority of the substructure. The original Portland stone façade will be retained, and the new floors will be of cross-laminated timber construction.

The existing seven-storey buildings at 206 Marylebone Road, comprising a purpose-built 1930s building for the National Cash Register Company and subsequent northern extensions dating to the 1960’s, are to be demolished and rebuilt, retaining only the basement retaining walls, and majority of the basement slab and existing foundations, and the 1930’s Portland stone façade, featuring its Corinthian colonnades.

New structural elements include a new concrete core and a steel frame with CLT superstructure slabs and hollowcore precast ground floor slab. A new core pile cap supports the new core, with small individual pile caps located under the columns where existing foundations do not have sufficient capacity for proposed loads. The existing column grid is largely retained to minimise remedial works required to existing foundations, and the requirement for new foundations off the original grid.

Davies Maguire carried out extensive research into various ways to minimise embodied carbon associated with construction of the proposed structure.

There are two key facets to the sustainability of the structural frame: embodied carbon, and circular economy. Retention and re-use of large portions of the existing building’s substructure, foundations, and façade provide large carbon savings, and the embodied carbon of the new elements is minimised by using an efficient steel frame and cross laminated timber (CLT) planks. The carbon sequestration associated with the timber planks is an added benefit, in addition to the lightweight floors minimising foundation loads and allowing construction of an additional storey. Timber is sourced from an industry-leading supplier whose energy efficient factory produces products with market beating embodied carbon figures.

Various options were investigated to improve the efficiency of the steel frame, however flexibility was limited by the need to maintain the existing column grid – a requirement for allowing reuse of the existing foundations – and constraints on the structural depth due to the façade retention. Additional ‘half-grid’ columns have been introduced, with the carbon cost of the new columns and foundations significantly outweighed by the reduction in embodied carbon associated with shortening the long spanning beams. Options such as using reclaimed steel, recycled (EAF) steel and X-carb steel have also been investigated. Davies Maguire engaged with stockists of reclaimed steel, who confirmed that around 10% of the steel requirement for the building at Stage 2 could be supplied from their stock. Close liaison will be maintained with EMR and other steel stockists as the project develops, to attempt to secure reclaimed steel suitable for the project.

To reduce embodied carbon of the new concrete, alternative cement replacements are being considered – namely limestone fines and calcined clays – but these are new technologies in the UK, and may not be available. A new technology called Neustark is also being investigated in collaboration with Aggregate Industries, in which the aggregates within the concrete mix are ‘soaked’ in carbon dioxide prior to the concrete being mixed, to sequester a small volume of carbon within the aggregates.